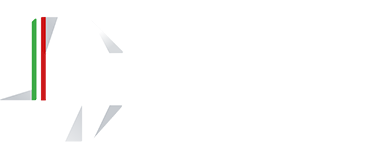

Our FANTAROC-FIL frame produces FANCY TWISTED YARNS and TECHNICAL YARNS from roving (roving frame or finisher), from sliver in cans and from yarn. The drafting group may feature one, two or three drafts and can process both short staple cotton fibers and long staple woollen fibers. To produce yarns from yarn (YARN TO YARN) there is a feeding creel on top of the external winding unit.

The highlight of this machine is its versatility due to the possibility of using several working modalities by leveraging and combining the two hollow spindles, the ring rail and the external winding unit.

In fact by means of special adaptors developed by us it is possible to transform the bottom hollow spindle into a take-up ring spindle which makes the machine suitable for any production requirement.

The external winding unit allows to reduce the length of the machine compared to a model with double hollow spindle and incorporated take-up cones.

This machine model is produced by us for over 20 YEARS and it has been very successful since the beginning for its flexibility and for the wide range of yarns that can be produced on one single machine.

Upon request it is possible to supply different types of needle heads to install in place of the hollow spindles to produce SPECIAL YARNS like TUBE YARNS, TUBE FILLED YARNS and AIRJET SOFTKNIT YARNS.

The conversion is a simple and quick operation.

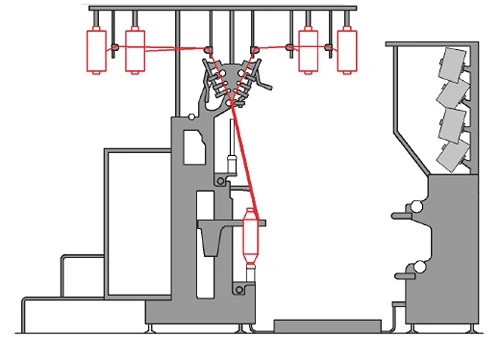

One hollow spindle (one binding yarn) and take-up on external cone

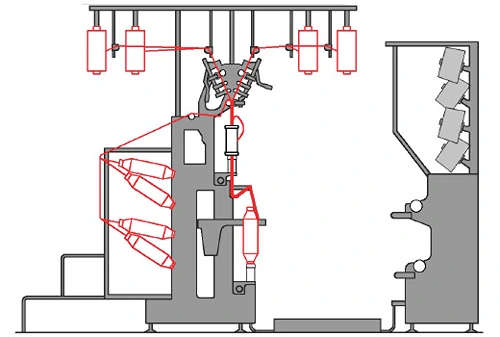

Two hollow spindles (two binding yarns) and take-up on external cone

One hollow spindle and take-up on bobbin

Direct spinning bypassing the hollow spindle and take-up on bobbin